Directed Printed Aligners(DPA)

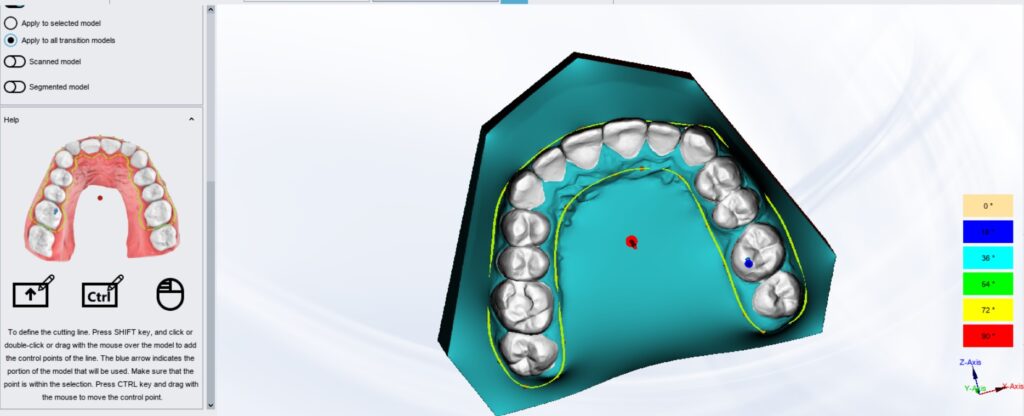

Today, the use of 3D printing is revolutionizing my profession as a dentist and is even being applied to orthodontics. Direct printed aligners (DPA) are a more comfortable and efficient treatment solution for patients. The added benefit of digitally printed clear aligners is that they allow the doctor to create a unique set of digital blueprints based on a patient’s mouth, which are then used to print out custom aligners for each phase of treatment. This allows for a closer fit and increased efficacy.

HISTORY

Dental malocclusion can affect dental aesthetics, oral hygiene, and periodontal health. There are many reasons patients seek orthodontic treatment, such as medical/dental reasons, improvement of appearance, and boosting self-esteem and confidence . A growing number of patients and doctors are choosing orthodontic treatments with aligners rather than conventional treatment with fixed orthodontic appliances like brackets and arch wires that are used to apply corrective forces to move the teeth into the desired position. These appliances cause lip discomfort and have an unpleasant appearance.

Clear aligners use transparent teeth positioners used in series, that is, a set of tooth positioners fabricated based on precise impressions or digital scans of the patient’s teeth, each producing different forces to progressively reach the planned dental alignment. The primary benefits are the clear transparent appearance of the devices and the ability to take them out when eating while maintaining oral hygiene, together with higher comfort and simplicity of use.

DPA

The use of clear aligners will spur the research and development of new materials specifically for use in direct 3D printing. Previously, orthodontic rings were used to straighten teeth; now, clear aligners are being used instead. This shows that the method of dental treatment has evolved over time. In the 1980s, 3D printing was invented by Charles Hull and it has since evolved into a mature field that is being increasingly utilized in dental and medical modeling . The ability to manufacture pieces layer-by-layer instead of common manufacturing methods that rely on machining, molding, and subtractive methods makes this technology very promising for future advances in oral surgery.

The ability to 3D-print custom-fitted aligners opens up new possibilities for orthodontic treatments. For example, the aligners can be used to correct mild to moderate cases of misalignment that may not have been appropriate for traditional braces. In addition, the aligners can be used to correct bite issues and even improve the aesthetics of the smile.

The use of direct printed aligners is also beneficial for orthodontists as it can significantly reduce the amount of time and money spent on each case. With 3D printing, orthodontists can create aligners faster and with greater accuracy than ever before. This means that patients can get straighter teeth in less time and with fewer appointments.

MATERIALS USED IN DPA

Most direct printed aligners are made with polymeric materials, such as polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). These materials are relatively inexpensive and can be printed quickly and accurately. PLA is a biodegradable thermoplastic that is commonly used for 3D printing because of its low cost, ease of use, and good mechanical properties. ABS is a thermoplastic with good impact strength and flexibility, making it a popular choice for 3D printing.

Another material used in the production of 3D-printed aligners is photopolymer resin, which contains a photoinitiator that hardens when exposed to ultraviolet (UV) light. This type of material is more expensive than the polymeric materials mentioned above, but it is more durable and less prone to warping. The process of printing with photopolymer resin is also more time-consuming than with PLA or ABS, as the resin must be cured layer-by-layer.

Lastly, there are several other materials that can be used to 3D print aligners, such as thermoplastic elastomers (TPE) and polyvinyl alcohol (PVOH). TPE is a rubber-like material that is highly flexible and can be used to create custom-shaped aligners. PVOH is a biocompatible material that is durable and resistant to saliva and bacteria.

In conclusion, there are several materials available for the 3D printing of aligners. Each material has its own advantages and disadvantages, so it is important to choose the material that best suits the patient’s needs. By using the right material, it is possible to create customized, affordable aligners quickly and accurately.